The code of practice requires that petroleum well decommissioning ensures “the environmentally sound and safe isolation of the well, protection of groundwater resources, isolation of the productive formations from other formations, and the proper removal of surface equipment." The code of practice and petroleum production lease conditions require that:

- the surface equipment is removed,

- the subsurface water aquifers are kept isolated from each other and from the coal seams (hydrocarbon zones),

- risk to future mining of the coal seams is minimised.

Coal seam gas well rehabilitation

In rehabilitating its well sites, AGL will ensure:

- The equipment at the top of the well is safely removed.

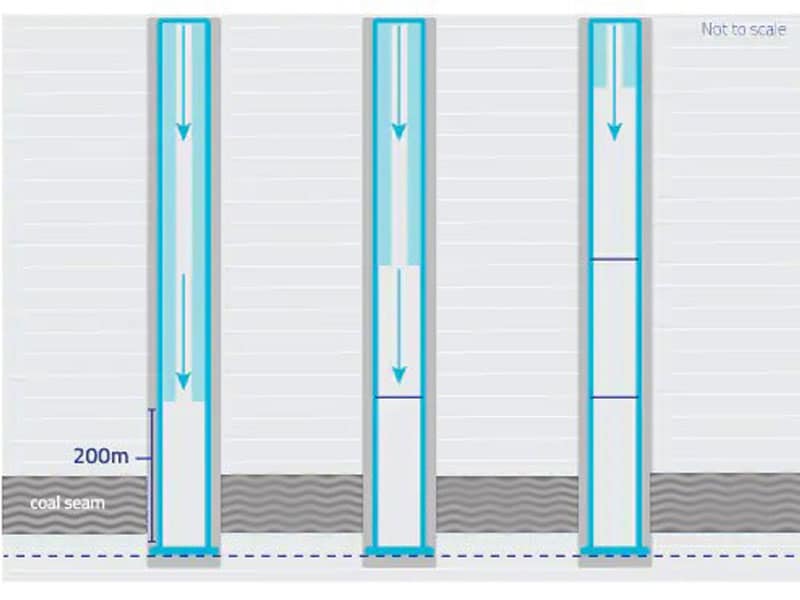

- Purpose-specific cement, which complies with the standards set by the NSW Government’s Code of Practice for Construction, operation and decommissioning of petroleum wells, is placed inside the well from bottom to top in stages.

- This cement seals the wellbore and adds to the integrity of the well.

- The well casing is cut off, at least 1.5 metres below the surface, so that it does not interfere with agricultural and other future land uses. A steel cap, containing data such as the name of the well, the well depth and when it was decommissioned, is welded to the top of the casing.

- The decommissioning works are overseen by the NSW Department of Planning & Environment (DP&E) and the NSW Environment Protection Authority (EPA) which is the lead regulator for petroleum activities in NSW, and conducted within stringent health, safety and environment guidelines. A full report is provided to the regulator once all decommissioning works have been completed for each well.